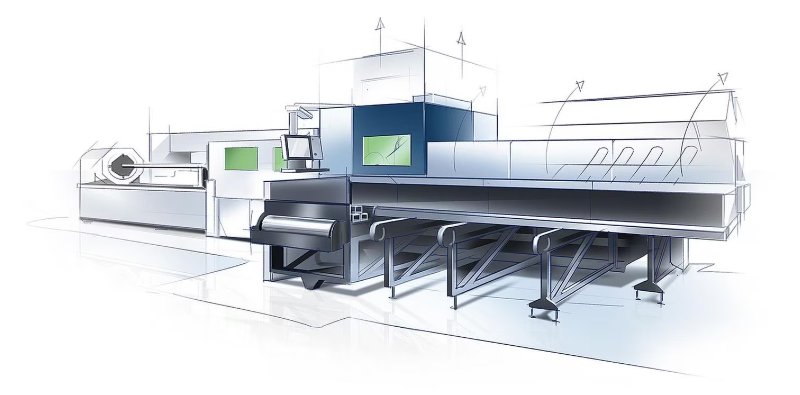

A metal tube laser cutting machine with an automatic loading and unloading system is a type of industrial machine that uses a laser beam to cut materials such as metal, wood, plastic, and others. The automatic loading and unloading system allows the machine to be more efficient, as it can handle materials without the need for manual intervention.

Metal tube Laser cutting machines with automatic loading and unloading systems are popular in industrial settings where large volumes of materials need to be cut quickly and efficiently. They offer several advantages, including improved accuracy, speed, and consistency, as well as reduced labor costs and downtime. Additionally, the automation of the loading and unloading process increases operator safety and reduces the risk of injury.

CNC metal tube laser cutting machine is an automatic tube cutter that realizes metal tubes (square tube, round tube, rectangular tube, channel beam, flange beam, U-tube, flat tube, and all types of shaped tubes and pipes) cut with the cooperation of computer and laser generator. CNC laser tube cutters can cut any programmed shape on metal tubes, and the laser can cut perfectly in any direction. The shape to be processed can be flexibly and quickly changed through computer programming design. The high flexibility of laser tube cutting machines provides strong technical support for more and more personalized metal processing, thereby reducing the number of molds used.

The modular design with the CNC controller realizes the unmanned and full data production of the tube-cutting operation. Compared with traditional metal tube cutting systems such as flame cutting, plasma cutting, and water jet cutting, the precision of laser-cut metal pipes is much higher. The CNC laser tube cutting machine can be flexibly adjusted according to these deformations, which is also beyond the reach of many traditional cutting methods.

CNC laser tube cutting machine adopts centralized operation, flexible cutting, automatic loading and unloading, and the clamping is convenient and fast. It adopts a precision rack and double drive mode, which is easy to maintain and maintain, and is maintenance-free. It adopts professional tube cutting software, which is the fundamental guarantee for effectively saving materials and improving cutting efficiency. Based on these advantages, laser tube cutting machines are widely used in the processing of round pipes, square pipes, rectangular pipes, and special-shaped pipes in fitness equipment, office furniture, kitchen cabinets, and other industries.

Advantages of CNC Metal Tube Laser Cutting Machine

1. Clamp design: The self-developed pneumatic clamp design is adopted on both sides, and the minimum tube can be clamped to 6mm(Smallest tube clamped on the tube laser market is 10mm). Many metal tube laser cutting machines on the market have a cutting length limit of 6 meters, our length is not limited.

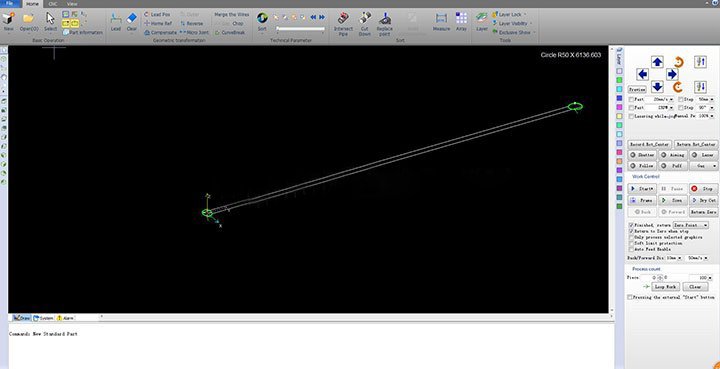

2. Intelligent operating system: one-button input cutting graphics, easy to operate. Rapid response to all shape tubes such as round tubes, square tubes, rectangle tubes, and oval tubes, greatly improving cutting efficiency. With a self-developed remote assistance system, our engineers can be used at any time.

3. Personalized customization: In the process of selling laser cutting machines, we often encounter some customers who think that the higher the power, the better, which is a wrong understanding. Therefore, we have always adhered to the customer’s product positioning as the standard, and customized optimization strategies to allow customers to spend the least money to enjoy the best equipment.

Why choose a Metal tube Laser cutting machine with automatic loading and unloading system

Choosing a metal tube laser cutting machine with an automatic loading and unloading system can offer several benefits to a manufacturing or fabrication business:

1. Increased efficiency: The automatic loading and unloading system can significantly reduce the time required for manual handling of the metal tubes, resulting in higher productivity and throughput.

2. Reduced labor costs: With an automatic loading and unloading system, the need for manual labor is minimized, reducing the associated labor costs.

3. Improved precision and accuracy: The laser cutting process is highly precise and accurate, ensuring that the metal tubes are cut to the exact specifications required, leading to fewer errors and wastage.

4. Enhanced safety: The automated loading and unloading system reduces the need for manual handling of heavy and bulky metal tubes, minimizing the risk of injuries and accidents.

5. Versatility: A metal tube laser cutting machine with an automatic loading and unloading system can handle a wide range of metal tube sizes and shapes, making it a versatile tool for various applications.

Overall, choosing a metal tube laser cutting machine with an automatic loading and unloading system can lead to significant improvements in productivity, efficiency, and safety, making it an excellent investment for businesses involved in metal fabrication and manufacturing.

Pre-Sale Service for Laser Cutting Machine:

1. Free Sample Cutting Service: For free sample cutting/testing, please send us your CAD file (.plt or .ai), and we will do the cutting in our factory and make a video to show you the cutting process and result, or send samples to you to check the cutting quality.

2. Progressing Solution Design: According to the customer’s product processing requirements, we can design a unique solution that supports higher manufacturing efficiency and better processing quality for customers.

3. Customized Machine Design: According to the customer’s application, we may revise our machine according to the customer’s convenience and high production efficiency.

After-Sale Service for Laser Cutting Machine:

1. We will supply the laser machine with a training video and a user’s manual in English for installation, operation, maintenance, and troubleshooting, and shall give technical guide by remote, such as TeamViewer, E-mail, Telephone, Mobile, Whatsapp, Skype, 24/7 online chat, and so on when you meet some problem of installation, operation or adjusting. (Recommended)

2. You can come to our laser machine factory for training. We will offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools, and a testing facility. Training Time: 3~5 days (Recommended)

3. Our engineer will do a door-to-door instruction training service at your local site. We need your help to deal with the visa formality, prepaid traveling expenses, and accommodation to us during the business trip and service period before their dispatch. It’s better to arrange a translator (if no English-speaking) for our engineers during the training period.

If you have an idea to get a free quotation for a CNC metal tube cutting machine, please answer the questions as follows and tell us by email, so that we can recommend the most suitable laser machine and quota the affordable price to you directly.

1. Do you need to cut metal sheets/plates, metal pipes/tubes only or both?

2. If need to cut tubes, What is your tube length, diameter and max thickness?

3. For cutting metal sheets, what is the max working area required?

4. After processing, what materials will be used for? (Applications)

5. Which seaport is the nearest to you?

6. Do you have any experience in the CNC laser metal tube cutting system?

7. What is your online chat way? Such as Skype and Whatsapp.

8. Are you an end user or reseller?

Reviews

There are no reviews yet.