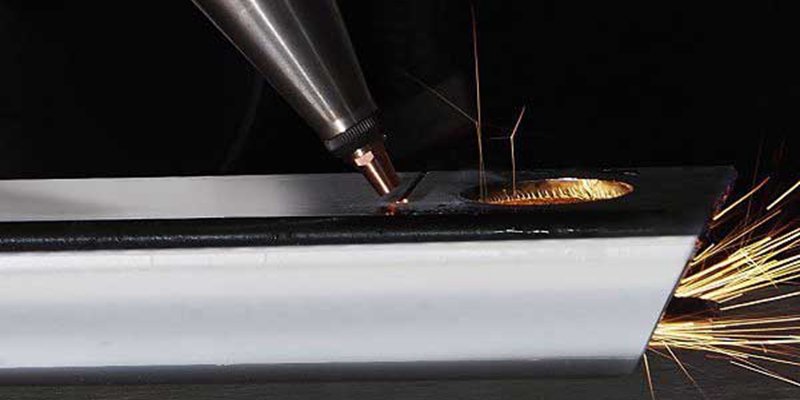

Burr is a common phenomenon in the laser cutting process(What should I do if there are burrs in the metal tube laser cutting machine?), which is characterized by irregular metal parts such as various sharp corners at the transition of the workpiece surface. The occurrence of burrs not only affects the appearance and precision of the product but also increases manpower and financial resources.

Table of Contents

ToggleInfluence of metal tube laser cutting burrs

The presence of burrs on the cutting edge of a laser tube cutting machine can have several effects, both positive and negative. Overall, while burrs on the cutting edge of a laser tube cutting machine can have negative effects on precision, structural integrity, and aesthetics, they can also have some positive effects in certain applications. Manufacturers need to carefully consider the impact of burrs on their specific application and adjust the cutting parameters accordingly to minimize the negative effects and maximize the positive ones.

Negative effects of burrs

1. Reduced precision: Burrs can create irregularities on the cut edges, leading to reduced precision and accuracy in the final product. This can be a significant issue for applications where tight tolerances are required.

2. Weakened structural integrity: Burrs can also weaken the structural integrity of the cut edge, making it more susceptible to cracking or breaking under stress. This can be a problem for applications where the cut edge is subjected to high loads or vibrations.

3. Impaired aesthetics: Burrs can also negatively impact the appearance of the cut edge, making it look rough or unfinished. This can be a concern for applications where the appearance of the final product is important.

Positive effects of burrs

1. Enhanced adhesion: In some cases, burrs can actually enhance the adhesion of the cut edge to other materials. This can be useful in applications where strong bonds are required.

2. Increased surface area: Burrs can increase the surface area of the cut edge, which can be beneficial for applications where a larger surface area is needed for bonding or other purposes.

Causes and solutions of metal tube laser cutting burrs

Setting parameters:

If burrs appear on the end face of the metal pipe laser cutting machine, first check the parameter settings and let experienced operators debug the equipment. It is impossible to cut high-quality workpieces only by the parameters provided by the machine. Solution:Try to adjust the cutting parameters to the best, such as air pressure flow, focal length, cutting speed, etc., which need to be adjusted many times.

Condition of the laser lens:

If the lens is dirty or damaged, it can cause burrs on the cut edge. Solution:Clean the lens or replace it if necessary.

Focus of the laser:

The deviation of the upper and lower positions of the laser beam focus generated by the laser cutting machine makes the energy not only concentrated on the workpiece, but the workpiece is not completely evaporated, thereby increasing the amount of slag, and it is not easy to be blown away, so the burrs are more likely to appear on the hat. Solution:Adjust the focus of the laser beam and check the cut quality.

Cutting gas:

The type of gas used during the cutting process can also affect the quality of the cut. Solution:Higher-quality cutting gas can reduce the formation of burrs.

Cutting nozzle:

Over time, the cutting nozzle can become worn or damaged, which can cause burrs on the cut edge. Solution: Replace the cutting nozzle regularly to ensure optimal performance.

Alignment of the laser:

If the laser is not properly aligned, it can cause the cut edge to have burrs. Solution: Check the alignment of the laser and adjust it if necessary.

Power of the laser cutter:

The output power of the laser cutter is not enough to effectively evaporate the metal, resulting in excessive slag and burrs. Solution:Check whether the laser cutting machine works normally. If it is not normal, it needs to be repaired and maintained in time; if it is normal, check whether the output value is correct.

Cutting speed:

If the laser is moving too slowly, it can cause the material to melt and stick to the edge, resulting in burrs. Solution:Increase the cutting speed to prevent this from happening.

Working time is too long:

The working time of the laser cutting machine is too long, which leads to unstable operation of the equipment and burrs. Solution:Turn off the laser cutter and restart it after a while to get enough rest.

The above are the causes and solutions of several common burrs. Only by understanding the root causes of the problems can they be effectively solved. If none of these steps solve the issue, it may be necessary to consult with a professional technician or the manufacturer of the laser tube-cutting machine for further assistance.