The portable 3-in-1 laser machine is a versatile all-in-one system that includes a handheld laser gun. With this laser gun, you can easily cut and weld metal as well as remove rust, paint, resin, coating, oil, and stains. This multipurpose laser machine is now available for purchase at a competitive cost price.

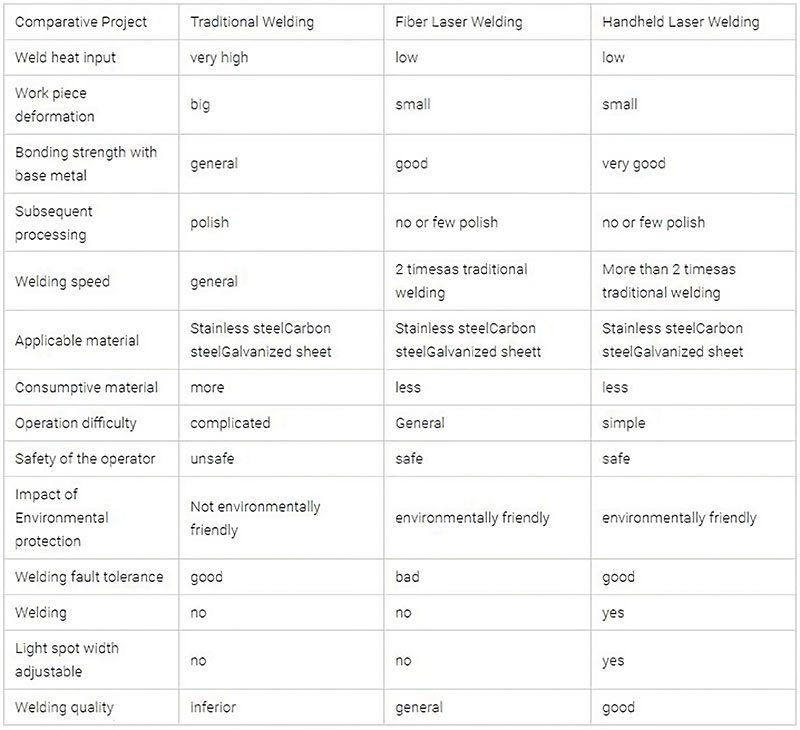

Features of Handheld Laser Welding Machine

A handheld laser welding machine is a type of portable fiber laser beam welding machine that couples the high energy fiber laser beams into the optical fiber, after long-distance transmission, then transformed into parallel lights through the collimating mirror to be focused on the workpiece to implement the welding. The fiber laser welder is more flexible to implement flexible transmission of non-contact welding for those difficult-to-weld sites. Manual laser beam welding can realize the spectrum separation on time and energy, it can do multi-beam welding at the same time, and it provides the conditions for high precision welding compared with traditional MIG & TIG welding, electric welding, and arc welding.

Advantages of Handheld Laser Welding Machine with Fiber Laser Beam

1. Handheld welding head is equipped with 1000w/1500w/2000w/3000w-watt fiber laser power, flexible, enabling outdoor welding.

2. Fast welding speed, 2-10 times faster than traditional welding.

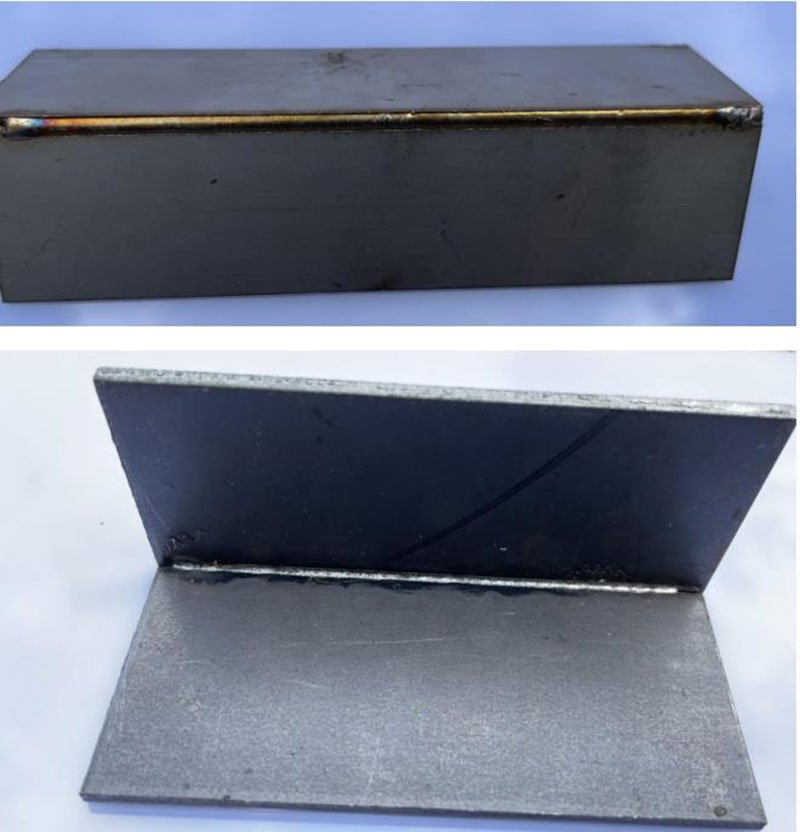

3. The welding seam is smooth and beautiful, large depth, and the small taper doesn’t need polish, saving time.

4. No deformation or welding scar, firm welding of the workpiece.

5. Laser welding has fewer consumables, low energy consumption, and long service life.

6. Safety, easy operation, and more environmentally friendly.

Wobble Laser Welding Head: Beautiful weld, fast speed, no weld marks, no discoloration, no later polishing.

Technical Parameters of Handheld Laser Welding Machine :

Laser Power:1000w/1500w/2000w/3000w

Laser WaveLength:1070nm

Fiber Length: Standard 10M

Welding Speed Range: 0-125mm/s

Cooling Chiller: Industrial Water Chiller Inside

Working Environment Temperature Range:-30-40℃, (low-temperature environment needs to add antifreeze )

Humidity Range of Working Environment:<70% No Condensation

Working Voltage:380V

Handheld Laser Welding Machine Applications

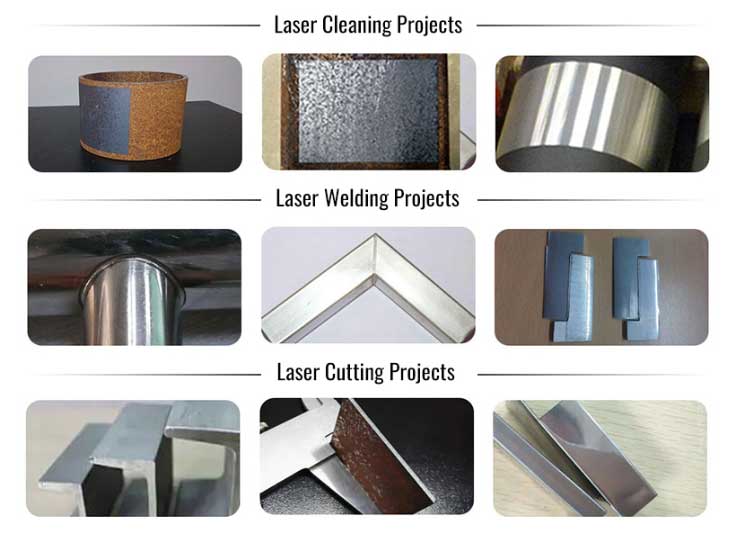

1. Handheld laser welding machine can be used for welding stainless steel, carbon steel, copper, aluminum, gold, chromium, silver, titanium, nickel, and other metals or alloys, it can also be used for a variety of welding between different materials, including copper – brass, titanium – molybdenum, titanium – gold, nickel-copper, and so on.

2. The laser cleaning gun is a compact and mobile tool that effectively eliminates rust, resin, coating, oil, stains, paint, and dirt from surfaces. Perfect for hobbyists and industrial manufacturing, it can greatly reduce machine maintenance costs and enhance cleaning performance.

3. The laser cutting gun is a singular, handheld laser cutter that can be utilized for cutting all varieties of metals. It offers the utmost in portability and convenience.

Handheld laser welder machine is widely used in kitchen cabinets, staircase elevator, shelf, oven, stainless steel door, window guardrail, distribution box, medical equipment, communications equipment, metal furniture, battery manufacturing, craft gifts, household, and other industries.

Why choose the Bluewo handheld laser welding machine?

1. Simple, easy to learn, flexible, and convenient; low requirements for operators, simple training is enough, simple operation, quick start, hand-held welding, flexible and convenient, not restricted by travel, easy to move; almost no maintenance, fewer consumables; welding speed Fast, beautiful weld seam, suitable for stainless steel, carbon steel, aluminum alloy welding, instead of traditional argon arc welding, YAG welding process.

2. The welding process has no spatter, can be precisely controlled, and the size of the spot can be adjusted, which reduces the requirements for the welding seam gap of the workpiece splicing; the welding seam quality is stable, the welding workpiece has no deformation, no welding scars, high passability, and strong applicability; the welding is firm and reduces Subsequent grinding process, improve efficiency and save cost.

3. High photoelectric conversion rate, low energy consumption, and long-term use can save a lot of costs.

4. Common welding methods include splicing welding, internal fillet welding, external fillet welding, lap welding, lap welding, and other spot welding or closed welding.

5. It has a contact safety protection function to avoid mistakenly emitting light, and ensure that the light is welded only when it is in contact with the part to be welded. Wear laser safety glasses when welding.

Reviews

There are no reviews yet.