Now more and more industrial manufacturers are choosing laser cutting machines( BENEFITS AND ADVANTAGES OF FIBER LASERS ),Choosing the best laser cutting machine for your business depends on several factors, such as:

Table of Contents

ToggleBest Laser cutting machine product requirements

1. The type and thickness of the materials you want to cut or engrave.

2. The size and shape of the products you want to make.

3. The budget and space you have available.

4. The level of quality and speed you need.

5. There are two main types of laser cutting machines: CO2 and fiber. CO2 lasers use a gas-filled tube to produce a beam that can cut or engrave a variety of materials, such as wood, acrylic, leather, paper, fabric, etc. Fiber lasers use a solid-state source to produce a beam that can cut or engrave metals and some plastics. Fiber lasers are more expensive but also more powerful and efficient than CO2 lasers.

Functional requirements of best laser cutting machine

1. Laser power: This determines how fast and deep you can cut or engrave your materials. Higher wattage means faster and deeper cuts but also higher cost and energy consumption. The optimal power depends on your material type and thickness.

2. Work area: This determines how large your products can be. Larger work areas allow you to cut or engrave bigger pieces or multiple pieces at once but also require more space and cost more. You should measure your materials and products before buying a laser cutter.

3. Versatility: This determines how many different types of materials and products you can make with your laser cutter. Some laser cutters can only cut or engrave certain materials while others can do both. Some laser cutters can also perform other functions such as 3D printing or CNC milling. You should consider what kind of products you want to make with your laser cutter.Such as metal cutting or plastic cutting or other materials cutting.

4. Safety features: This determines how safe it is to use your laser cutter. Laser cutting machines produce high-intensity beams that can cause burns, fires, eye damage, etc. You should look for features such as water cooling systems, ventilation systems, emergency stop buttons, protective glasses, etc.

5. Cooling and Ventilation: Machines tend to heat up when in use due to excessive heat generated from current and friction when moving parts rub against each other and other. It is therefore important to buy a laser cutting machine with appropriate cooling system within to counter this heat. Else, the working environment could become very uncomfortable. Keeping these factors in mind all our machines come with a high quality chiller which when attached gives a proper cooling system with low maintenance.

why to choose laser cutting machine according to the material

Choosing a laser cutting machine according to the material is important for several reasons, such as:

1. The cutting speed and quality: Different materials have different densities, thicknesses, and melting points that affect how fast and how well they can be cut by a laser. A higher laser power output can cut denser and thicker materials faster and cleaner than a lower one. However, some materials may char or burn when exposed to high heat. Therefore, you should choose a laser cutting machine that matches the power required for your material type and thickness.

2. The cutting precision and accuracy: Different materials have different reactions to the laser beam that affect how precise and accurate they can be cut by a laser. Some materials may shrink or warp when heated by the laser. Some materials may have uneven surfaces or contain glue that prevents good cuts. Therefore, you should choose a laser cutting machine that can adjust the focal length and intensity of the beam according to your material characteristics.

3. safety and environmental impact: Different materials have different hazards and emissions when cut by a laser. Some materials may produce toxic fumes or smoke that can harm your health or damage your machine. Some materials may be flammable or explosive when exposed to sparks or flames. Therefore, you should choose a laser cutting machine that has proper ventilation and cooling systems, protective glasses, emergency stop buttons, etc.

I hope this helps you choose the best laser cutting machine for your business.

What are the wearing parts of the fiber laser cutting machine?

Although the service life of the laser cutting machine is very long, there will also be consumable parts, so when your business is running, you should also have some spare parts.

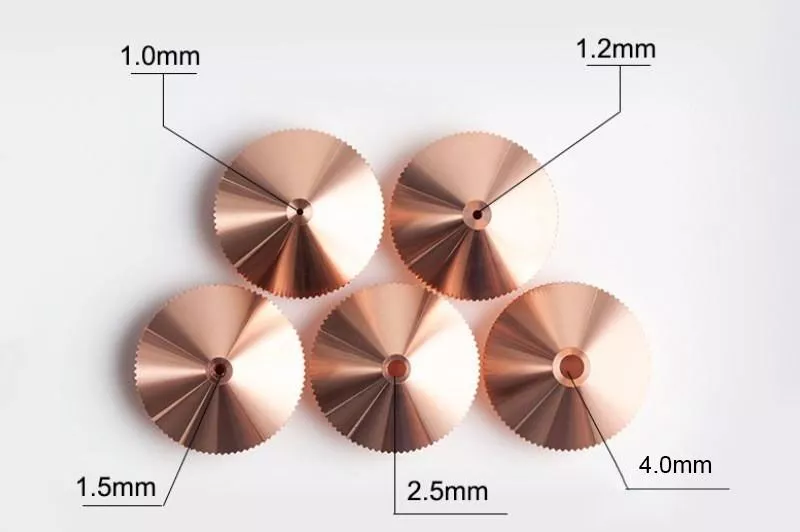

1.laser nozzle :

The nozzle can assist the gas to be ejected quickly, which can effectively prevent the debris from bucking up and rebounding, thus protecting the focusing mirror. At the same time, it can control the gas diffusion area and size, which will affect the cutting quality of the fiber laser cutting machine. What’s more, the aperture size of the nozzle will vary depending on the thickness of the cutting material. The replacement period is about two months.

2.Laser lens:

The laser protection lens mainly acts on the fiber laser cutting machine to block debris splash during the fiber laser cutting machine work, and prevent spatter from damaging the lens, and to coat the two sides with a high damage threshold anti-reflection film to reduce reflection. Generally speaking, The replacement period of these lenses is about 3 months, depending on the actual processing conditions.