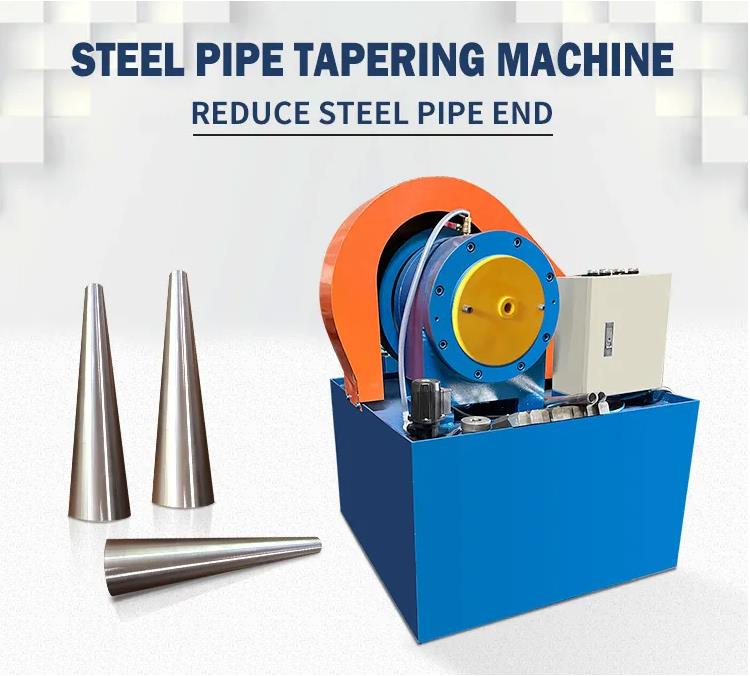

Best round tube end forming machine(End forming machine), Easy To Operate Round Metal Tube Tapering Diameter Reducing Cone Pipe End Forming Machine

A Taper pipe machine(Tube end forming machine) is used to process metal round pipes into tapered pipes. This machine has the characteristics of low noise, easy operation, high output and stable performance. The machine mold replacement is simple and easy to operate, and can process metal tubes of different shapes with the cooperation of corresponding molds, and supports customization to meet different sizes. The machining time is short, the work efficiency is improved, and the surface of the finished product is smooth and there is no scar on the surface of the finished product.

Bluewo tube end forming machine manufacturers

Applications:

A cone pipe machine(Tube end forming machine) is also called (a necking machine, hollow pipe, cone machine, etc.) and can process iron pipe, steel pipe, aluminum pipe, carbon steel, and copper pipe into various daily necessities.

Widely used in furniture, anti-theft doors, and windows, lighting, sporting goods, hardware processing, automobiles, and other industries, it can process tables and chairs, bed legs, lampposts, stair handrails, fence handrails, light poles, golf clubs, baseball poles, fishing poles, decorative tubes, etc.

Main Specifications | 38 Type | 50 Type | 76 Type |

Processing Range | 12 mm -38 mm | 12 mm – 51mm | 12 mm – 76 mm |

Pipe/Tube Thicknes | 0.6 mm – 1.2 mm | 0.6 mm -1.2 mm | 0.6 mm – 1.5 mm |

Forming Length | 300 mm | 400 mm | 400 mm |

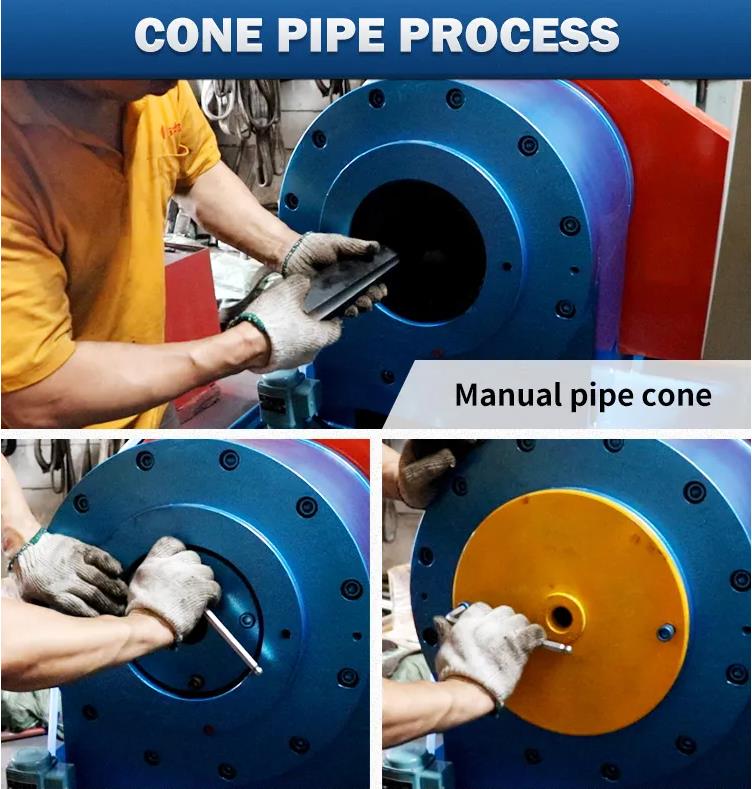

Working principle:

The outer tapered shape of the pipe of the tapered pipe machine is determined by the mold, and the embossing machine mold is composed of a mold, which is stuck in the slot of the body, and the inside is inlaid with 4 wedge-shaped irons. The wedge-shaped iron manually adjusts the extrusion angle before extrusion. After the motor rotates, it drives the mold to rotate and extrude around the pipe. After die-casting, the pipe can be pulled out backward.

We will design corresponding molds according to customer needs. And the finished steel pipes are mainly used in furniture, kitchenware, architecture, etc.

If you need our pipe tapering machine, please tell us:

1. The diameter & thickness of the pipe before the taper;

2. The diameter of the pipe after the taper.

If you have an idea to get a free quotation for a tube end forming machine, please answer the questions as follows and tell us by email, so that we can recommend the most suitable tube end forming machine and quota the affordable price to you directly.

1. Provide the pipe material you need to process, preferably describe the purpose of your processing and the standards required for the product.

2. What is the local voltage, that can ensure the normal operation of the machine?

3. Which seaport is the nearest to you?

4. Do you have any experience in Die punching?

5. What is your online chat way? Such as Skype and WhatsApp.

6. Are you an end user or reseller?

Reviews

There are no reviews yet.